Mastering Process Optimization Techniques

Process optimization techniques are really just a collection of structured methods for making your business run better. The idea is to systematically hunt down and eliminate waste, cut down on errors, and boost overall efficiency. These are the tools you use to take a hard look at how work actually gets done, transforming clunky, expensive operations into systems that are fast, high-quality, and built to scale.

Unpacking the Goal of Process Optimization

Imagine one of your core business workflows is a leaky pipe. Every single drip represents wasted time, squandered money, and your team's precious energy going down the drain. Process optimization is simply the art and science of finding and patching those leaks, one by one. The goal is to make sure every resource you have is directly contributing to creating value.

At its heart, the mission is straightforward but incredibly powerful: to create more value with less waste. This is about so much more than just trimming the budget; it's about building a fundamentally stronger and more resilient company from the inside out.

Why Optimization Is Essential

For any modern business that wants to grow sustainably, mastering process optimization isn't a "nice-to-have"—it's critical. These techniques give you a reliable framework for spotting the bottlenecks, redundancies, and hidden inefficiencies that are quietly holding you back. Without a clear strategy, it's easy to get stuck with outdated workflows that kill productivity and leave both your team and your customers frustrated.

When you put these methods into practice, the advantages are clear:

- Reduced Operational Costs: You stop wasting resources and labor by cutting out pointless steps and automating tasks that don't require a human touch.

- Enhanced Quality and Consistency: When processes are standardized and fine-tuned, you dramatically reduce the chances of human error. This leads to more dependable, higher-quality work.

- Improved Customer Satisfaction: Think about it: faster service, fewer mistakes, and reliable quality all add up to a much better customer experience. That's how you build loyalty.

- Increased Scalability: Efficient processes can handle a surge in demand without needing a massive injection of new resources. This allows your business to grow without the growing pains.

A Foundation Built on History

This drive for efficiency is nothing new. The roots of process optimization go all the way back to the Industrial Revolution, but they really started to take modern shape with Frederick Winslow Taylor's "Scientific Management" in the late 19th century. His work, which used time and motion studies to figure out the most efficient way for people to work, laid the foundation for modern industrial engineering and the data-first techniques we rely on today.

At its core, process optimization is an ongoing commitment to excellence. It’s about creating a culture where every team member is empowered to ask, "Is there a better way to do this?" and has the tools to find the answer.

This kind of thinking prepares your organization for even more powerful methodologies. To see how this concept of continuous improvement has evolved, it’s worth exploring related fields like the What Is DevOps Methodology, which focuses on breaking down silos between development and operations teams to speed everything up. When you start seeing your business through a lens of constant refinement, you’re laying the groundwork for true operational excellence.

Core Methodologies for Lasting Improvement

While the latest tech grabs all the headlines, the real secret to lasting efficiency lies in a few time-tested principles. These core methodologies are the bedrock of modern optimization, giving you a proven roadmap to tackle operational challenges head-on. They provide the "why" behind the "how."

Think of them like different specialists you’d hire for a job. You wouldn't call an electrician to fix a leaky pipe, and you shouldn't use a speed-focused framework when your biggest problem is quality control. Knowing the unique strengths of Lean, Six Sigma, and Business Process Management (BPM) is your first step to picking the right tool for the job.

Lean: The Relentless Pursuit of Value

At its core, the Lean methodology is obsessed with one thing: maximizing customer value while mercilessly cutting waste. It got its start on the factory floors of Japan but has since become a powerhouse philosophy in nearly every industry, from software to healthcare.

Picture a Michelin-star chef in their kitchen. Every movement is precise. Every ingredient is within arm's reach. Every step is sequenced to eliminate delays. That’s Lean in a nutshell—a systematic way to identify and destroy any activity that doesn't add something the customer actually cares about.

Lean puts waste into eight distinct buckets, famously known as the 8 Wastes of Lean.

- Defects: Work that’s wrong and needs to be redone.

- Overproduction: Making too much, too soon.

- Waiting: People or projects stuck waiting for something to happen.

- Non-Utilized Talent: Not using the brainpower and skills of your team.

- Transportation: Moving things around more than necessary.

- Inventory: Piling up materials or products that tie up cash and space.

- Motion: Unnecessary physical movement, like walking across the office for a tool.

- Extra-Processing: Doing more work than the customer is willing to pay for.

By zeroing in on this list, teams can become waste-hunting experts. If you’re interested in diving deeper into these approaches, you can learn more about different business process improvement methods and find the perfect fit for your goals.

Six Sigma: The Data-Driven Quest for Perfection

If Lean is the efficient chef, Six Sigma is the meticulous scientist in the lab. This is a highly disciplined, numbers-driven approach aimed at achieving near-perfect quality. The goal is to reduce defects to a mind-bogglingly small number: no more than 3.4 defects per million opportunities.

Six Sigma gets there with a five-step framework called DMAIC:

- Define: Pinpoint the exact problem, project goals, and what the customer needs.

- Measure: Gather data to get a clear picture of how the process is performing right now.

- Analyze: Dig into the data to find the root cause of the problem. No guessing allowed.

- Improve: Design and roll out a solution that directly addresses that root cause.

- Control: Put systems in place to make sure the fix sticks and the problem doesn't creep back in.

This structured, scientific method completely removes guesswork from the process. Instead of acting on a hunch, Six Sigma forces you to use hard data to prove where things are broken and confirm that your solution actually worked.

This data-first mindset isn't new. Optimization as a formal field exploded during World War II, when mathematicians developed techniques like linear programming to solve incredibly complex military logistics problems. That early work laid the foundation for the data-centric methods we rely on today in finance, manufacturing, and tech.

Business Process Management: A Holistic Approach

Lean and Six Sigma are fantastic for fixing specific processes, but what about the big picture? That’s where Business Process Management (BPM) comes in. BPM isn't a one-and-done project; it’s an ongoing discipline for managing and improving all of an organization’s interconnected workflows.

Think of it as the strategic architect making sure every individual process—from sales to support—works together to hit the company's biggest goals.

To make it even clearer, let's break down how these powerful methodologies stack up against each other.

Lean vs Six Sigma vs BPM At a Glance

The table below gives you a quick snapshot of the key differences between these powerful process optimization techniques.

| Methodology | Primary Focus | Main Goal | Best For |

|---|---|---|---|

| Lean | Speed and Waste Elimination | Maximize customer value by removing non-value-added activities. | Reducing cycle times, improving workflow efficiency, and cutting operational costs. |

| Six Sigma | Quality and Defect Reduction | Achieve near-perfect quality and consistency through statistical analysis. | Solving complex quality problems, reducing errors, and improving process predictability. |

| BPM | End-to-End Process Orchestration | Align all business processes with strategic goals for continuous improvement. | Managing complex, cross-functional workflows and creating a culture of ongoing optimization. |

Each of these frameworks offers a different but equally valuable lens for viewing your operations. The key is knowing when to grab the microscope (Six Sigma), the stopwatch (Lean), or the blueprint (BPM).

How AI and Automation Fit Into the Picture

While the classic optimization frameworks give you a solid game plan, today's technology is the high-octane fuel that makes it all happen faster and smarter. When you combine proven methods like Lean or Six Sigma with modern AI and automation, you get a powerful one-two punch that shifts your business from constantly putting out fires to proactively preventing them.

This isn't about throwing out the old playbook. It’s about making it work better. Think of it like this: If a Six Sigma Black Belt is the detective scrutinizing the evidence, then AI is the high-tech forensics lab, uncovering clues and patterns in the data that are completely invisible to the naked eye.

Robotic Process Automation: Your Digital Workforce

The easiest way to dip your toes into automation is usually with Robotic Process Automation (RPA). Picture a digital team member who works around the clock, never gets tired, and executes mind-numbing, repetitive tasks flawlessly. That’s essentially what RPA delivers.

RPA "bots" are just software scripts designed to mimic human actions on a computer. They can log into apps, shuffle data between systems, fill in forms, and organize files. It’s the perfect solution for taking the grunt work off your team's plate so they can focus on work that actually requires a human brain.

A few common uses include:

- Automated Data Entry: No more manually copying customer info from a spreadsheet into your CRM.

- Invoice Processing: Bots can "read" incoming invoices and plug the data right into your accounting system.

- Report Generation: Instead of someone spending hours every Monday pulling numbers, a bot can compile a perfect report from multiple sources and have it waiting in your inbox.

AI and Machine Learning: From Reactive to Predictive

If RPA is the "hands" doing the work, think of AI and Machine Learning (ML) as the "brain" doing the thinking and predicting. These tools take process optimization to a whole new level—from just analyzing what went wrong to predicting what will happen next. ML algorithms can sift through mountains of data to spot tiny inefficiencies, forecast future roadblocks, and even suggest the best course of action.

The rise of machine learning and artificial intelligence has transformed process optimization by introducing advanced algorithms that have significantly improved applications in data analysis and pattern recognition. To delve deeper into this evolution, discover more insights about the historical development of optimization and its applications.

For example, an e-commerce business can use AI to get incredibly accurate with its demand forecasting. By analyzing past sales, seasonal trends, and even social media chatter, it can predict which products will fly off the shelves. This lets them nail their inventory—no more frustrating stockouts or money tied up in products nobody wants. It’s a classic Lean principle, just supercharged with a dose of predictive analytics.

Finding the Best Spots to Automate

To make any of this work, you first have to know where your biggest opportunities are hiding. This is where a classic technique like Value Stream Mapping (VSM) is invaluable. A VSM is basically a detailed flowchart of a process from the very first step to the last, showing every action, delay, and point where work is handed off.

Lay it all out visually, and the bottlenecks and repetitive tasks practically jump off the page. Those are your prime targets for automation. For an even deeper look, companies are now using more advanced tools. You can learn how to automatically find and visualize your real-world workflows by exploring https://makeautomation.co/what-is-process-mining/ in our detailed guide. This technique uses the digital footprints in your existing systems to build a live, dynamic map of how work actually gets done.

To see how this plays out in the real world, think about how automating sales processes can completely change the game by getting rid of tedious manual follow-ups and data entry. When you combine a clear process map with smart automation, you create a system that not only works well today but is also nimble enough to handle whatever comes next. That's what modern process optimization is all about.

Choosing and Implementing the Right Technique

Knowing the different process optimization techniques is one thing, but actually picking the right one for the right problem? That’s where the real magic happens. This isn't about chasing the latest buzzword; it's about making an honest diagnosis of what's really holding your business back. Get this choice right, and you've already won half the battle.

Think of it like a doctor treating a patient. You wouldn't prescribe heart medication for a broken leg. In the same way, you need to match the business "symptoms"—like sluggish delivery times or a spike in customer complaints—with the correct "remedy," whether that’s Lean, Six Sigma, or a heavy dose of automation.

Start by Defining Your Core Problem

Before you jump to a solution, you need to be crystal clear on the problem itself. Nearly every process headache boils down to one of three things: speed, quality, or cost. Nailing this first step is absolutely critical because it points you directly to the most suitable methodology.

-

Is it a quality issue? If you're seeing high defect rates, inconsistent work, or customers constantly flagging errors, you have a quality problem. This is a classic signal to bring in a data-heavy approach like Six Sigma, which is designed specifically to hunt down and eliminate the root causes of mistakes.

-

Is it a speed bottleneck? Are projects constantly getting stuck in limbo? Is your time-to-market painfully slow? Are you leaving customers waiting? These are all speed problems. The Lean methodology, with its laser focus on cutting waste and improving flow, is the ideal tool for unclogging your workflows.

-

Is it a cost overrun? If operational expenses are creeping up or a specific process is just eating up too many resources, your challenge is cost. Both Lean and automation tools like RPA are fantastic for this, either by trimming unnecessary steps or by swapping expensive manual work for efficient digital labor.

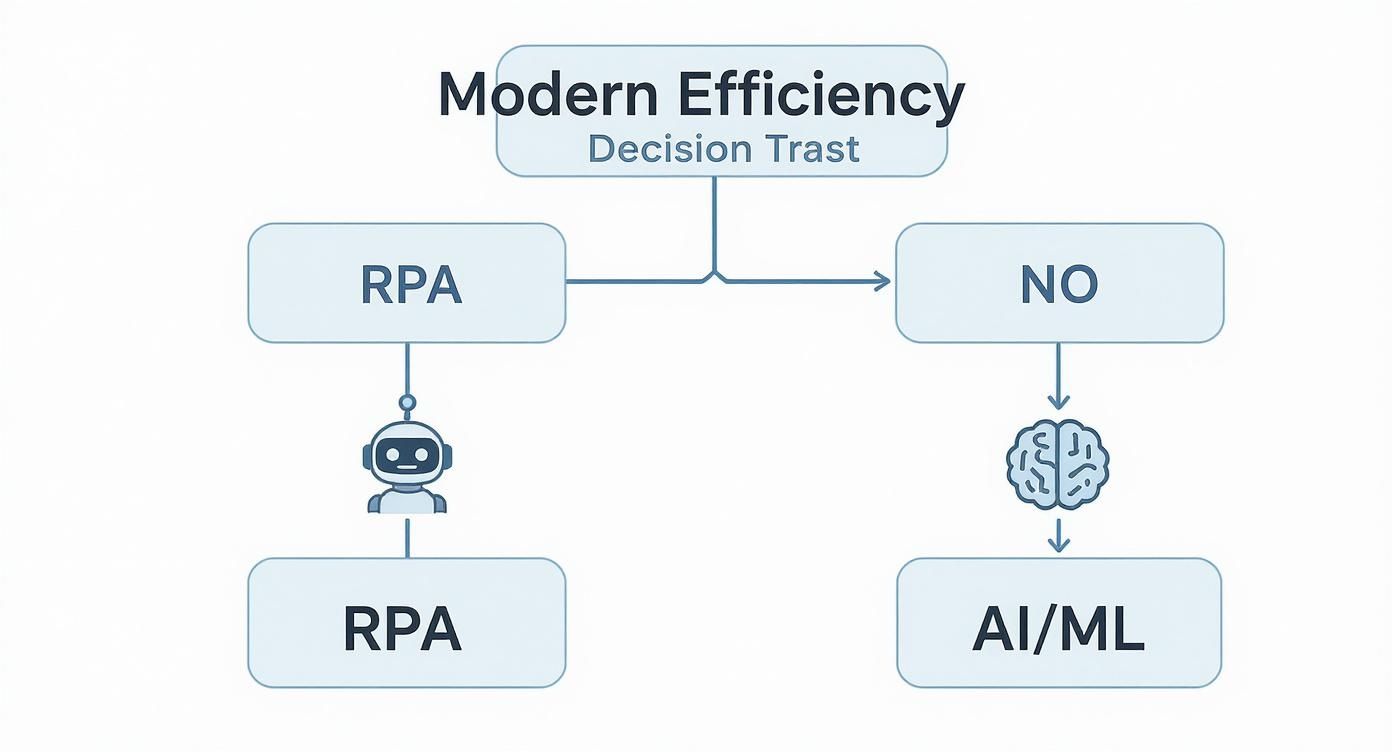

This simple flowchart can help you visualize the decision for modern efficiency challenges.

As you can see, the path diverges: repetitive, rule-based tasks are perfect candidates for RPA, while more complex processes that require judgment are better suited for AI and machine learning.

Establish Your Success Metrics Early

Once you've zeroed in on the problem and a potential solution, the next step is non-negotiable: define what success actually looks like. You have to set clear Key Performance Indicators (KPIs) before you touch a single thing. Without a baseline, you'll have no way to prove your efforts made a real difference.

For instance, if you're trying to fix a slow customer onboarding process, your KPIs might be:

- Reduce average onboarding time from 10 days to 3 days.

- Decrease the number of manual touchpoints from 15 to 4.

Setting measurable goals transforms your optimization project from a vague "let's make things better" initiative into a focused, results-driven mission. It provides a clear finish line and makes it easy to demonstrate ROI.

Secure Team Buy-In and Start Small

Honestly, the biggest roadblock you'll face is rarely the technology; it's the people. Change is hard, and most people are naturally resistant to it. You absolutely have to get your team on board from day one. Clearly explain the "why" behind the new approach, focusing on how it will make their jobs easier, not just different.

And please, don't try to boil the ocean. Instead of a massive, company-wide overhaul, start with a small pilot project. Find a single process that's high-impact but relatively low-risk and test your chosen technique there. This gives you a safe space to work out the kinks and—most importantly—to score a quick, visible win.

A successful pilot creates incredible momentum. When other departments see one team slash their error rate by 50% or cut their manual workload in half, they won't just accept the change—they’ll start demanding it for themselves. This is how you turn skepticism into genuine excitement for a full-scale rollout.

Process Optimization in the Real World

Knowing the theory is great, but seeing these techniques actually work is where the magic happens. Let's get out of the textbook and look at some practical, step-by-step roadmaps for fixing the kind of business functions you probably deal with every single day.

These are real-world scenarios where a smart mix of automation and workflow redesign solves nagging problems, frees up people's time, cuts down on errors, and directly helps the bottom line.

Transforming Customer Onboarding

A clunky, manual onboarding process is one of the fastest ways to kill a new customer's enthusiasm. When a client is forced to deal with delays, repeat requests for the same information, and confusing communication, that initial excitement just evaporates. It's a classic efficiency bottleneck crying out for a fix.

The Problem: A SaaS company was struggling with a painful onboarding process. It involved a messy trail of emails, staff manually entering customer data into three different systems (their CRM, billing platform, and the product itself), and booking welcome calls by hand. The whole thing took, on average, over seven days. As a result, a shocking 15% of new customers were canceling within their first month.

The Optimization Roadmap:

- Map the Current State: The first step was to get everything out on a whiteboard. Using value stream mapping, the team tracked every single action from the moment a contract was signed to the customer logging in for the first time. The bottlenecks became obvious: the manual data transfers and the gaps in communication were slowing everything down.

- Automate the Data Sync: They set up a simple automation. Now, when a salesperson marks a deal as "Closed-Won" in the CRM, it instantly triggers a chain reaction: a new user account is created in the product, an invoice is generated in the billing system, and all the records are updated at once. No more copy-pasting.

- Standardize Communications: They built an automated welcome email sequence. The first email, with login details, goes out immediately. Over the next few days, the customer automatically receives helpful links to tutorials, a calendar link to book a demo, and an introduction to their support contact.

- Create a Welcome Dashboard: To get everything out of email, they started creating a simple project management board for each new customer. It serves as a single source of truth, showing a clear checklist of onboarding steps and key milestones.

The Measurable Outcome: The results were dramatic. The company slashed its average onboarding time from 7 days to just 24 hours. Even better, first-month churn caused by a bad onboarding experience plummeted to less than 3%.

This is the perfect illustration of how automation does more than just speed things up. It completely changes the customer experience, creating a smooth, professional, and reliable journey right from the start.

Overhauling Lead Generation and CRM Management

In sales, speed is the name of the game. A slow, disorganized process for handling new leads is like setting marketing dollars on fire. And relying on manual data entry isn't just slow—it's a recipe for costly mistakes that can stop a follow-up in its tracks.

The Problem: A B2B agency’s sales team was manually copying lead info from website forms and LinkedIn into their CRM. The delay was killing their momentum; it often took over 48 hours to make first contact. They estimated that a full 20% of their leads were either lost to data entry errors or just fell through the cracks entirely.

The Optimization Roadmap:

- Step 1: Centralize Lead Capture: First, they connected all their lead sources—web forms, chatbots, downloadable guides—directly to the CRM. Now, new leads are created automatically and in real-time. The manual work is gone.

- Step 2: Automate Lead Assignment: They set up simple rules to instantly route new leads to the right salesperson based on factors like territory, industry, or company size. This ensures every lead has a clear owner from the second it comes in.

- Step 3: Trigger Instant Follow-Up: The moment a lead is assigned, two things happen automatically: a task pops up for the salesperson, and a personalized introductory email is sent from their account.

The Measurable Outcome: The agency saw a 90% reduction in lead response time, with most new inquiries getting a personal touch in under 15 minutes. Because no lead was ever forgotten again, the number of qualified meetings they booked jumped by 60% in the very first quarter.

Putting Your Optimization Strategy into Action

All the theory and strategic mapping in the world won't make a difference until you actually put it to work. This is the crucial final step: translating your well-designed plans into real business results. And in today's world, modern automation platforms are the engine that makes it all happen.

Forget about needing complex code or waiting on long, expensive development cycles. These tools give you a visual, intuitive way to build the workflows you've imagined. With a no-code workflow builder, you can redesign, test, and launch automated processes just by dragging and dropping elements on a screen. This makes powerful process optimization techniques accessible to anyone on the team, not just developers.

This is the jump from manual work to automated systems where the real magic happens. You're no longer just talking about improvements—you're actively building them. To make sure you're starting on solid ground, take a look at our guide on what is process documentation. It’ll help you ensure your plans are crystal clear before you start building.

Solving Common Business Problems with No-Code Automation

The real value of these platforms is how they solve the everyday operational headaches that eat up your time and money. This isn't about abstract ideas; it’s about using automation to fix specific, painful bottlenecks in your business.

Just think about these practical examples:

-

Connecting Siloed Applications: Most companies have data stuck in different places—a CRM over here, a project management tool over there. Automation acts like a digital glue, syncing information between apps automatically. When a contact is updated in one system, it's updated everywhere, creating a single source of truth.

-

Building Automated Approval Workflows: We’ve all been stuck waiting for a manual approval. It’s a classic bottleneck. An automated workflow can instantly route requests to the right person, send reminders, and move things along the second an approval is given. The waiting game is over.

-

Setting Up Intelligent Triggers: What if your systems reacted to events in real time? With intelligent triggers, a new customer signing up can automatically kick off a personalized onboarding sequence. An urgent support ticket can instantly alert the right team member. The system just works.

By translating strategic goals into automated actions, you turn your optimization plans into a living, breathing system that works for you 24/7. This isn't just about efficiency; it's about building an operational backbone that is resilient, scalable, and consistently excellent.

Modern tools finally give you the power to put your strategies into action with speed and precision. This hands-on approach guarantees your efforts lead to measurable improvements in cost, quality, and speed, truly changing your business from the inside out.

Got Questions? We've Got Answers

As you start digging into process optimization, a few common questions always pop up. Let's tackle them head-on so you can move forward with confidence.

Process Improvement vs. Process Optimization: What's the Real Difference?

It’s easy to use these terms interchangeably, but they actually point to two different mindsets.

Process improvement is all about making what you currently do better. Think of it like fine-tuning a car engine—you're making small adjustments to boost performance. You’re fixing the obvious snags and making incremental gains without changing the fundamental way things work.

Process optimization, on the other hand, is a complete rethink. It asks: "Is this the absolute best way to get this done?" It’s less about tuning the engine and more about asking if you should be building an electric motor instead. Optimization aims for peak efficiency, even if it means tearing down the old process and starting from scratch.

The real difference is scope. Improvement refines the existing path, while optimization seeks the best possible path, period.

Can Small Businesses Do This Without a Big Budget?

Absolutely. A lot of small business owners think optimization is reserved for huge companies with deep pockets and teams of consultants. That's a myth. You can get started and see real results without spending a fortune.

Here's how to get the ball rolling:

- Pick One Big Problem: Don't try to boil the ocean. Find the single most painful process in your business—is it chasing down invoices? Onboarding new clients? Start there. A single, focused win will build momentum.

- Lean on Free and Low-Cost Tools: You don't need enterprise software. There are tons of great tools with generous free plans for project management, workflow mapping, and simple automation. Get creative with what's already available.

- Ask Your Team: The people doing the work every day know exactly where the friction is. Create a simple channel—even just a shared document—where they can drop ideas. You'll be amazed at what they come up with.

How Do I Actually Measure the ROI?

You can't just feel like things are better; you have to prove it. Tracking the return on investment (ROI) for your optimization efforts is how you get buy-in to do more. The good news is, it's not as complex as it sounds.

The formula is simple: quantify the gains and subtract the costs. Focus on metrics that speak the language of business—time, money, and customer happiness.

Here are a few things to measure:

- Hours Reclaimed: Add up the time saved by automating or eliminating tasks. Multiply those hours by the average employee wage to put a real dollar value on it.

- Costly Errors Avoided: How many mistakes did the old process cause? A 20% reduction in shipping errors, for example, is a hard number you can tie directly to saved cash on returns and replacements.

- Productivity Boosts: Are you getting more done with the same team? Track the increase in support tickets closed, leads qualified, or reports generated per week.

- Happier Customers: A smooth, efficient process makes for a better customer experience, which means they stick around longer. Even a small bump in retention can have a huge impact on revenue down the line.

When you can connect your work to these kinds of tangible results, optimization stops being a "nice-to-have" and becomes a core driver of your business's success.

Ready to put these ideas into action? MakeAutomation builds the automated systems that bring process optimization to life. We work with B2B and SaaS companies to design scalable workflows for lead generation, onboarding, and beyond. Reclaim your time and boost your ROI today.